The Third Part Inspection Service

- Location: China

- FOB Price: 150 ~ 180 / Case ( Negotiable )

- Minimum Order Quantity: 1 Case

- Packaging Detail: according to client's requirement

- Delivery Time: 1-2 days Day

- Supplying Ability: 99999 Case / Day

- Payment Type: Other, PayPal, Western Union, T/T

Product Description

Quality Inspection Service

Our network comprises over 50 professionally trained inspectors across 20+ major Chinese cities. All inspectors possess college degrees and a minimum of five years of quality inspection experience, enabling them to understand client requirements and local supplier quality dynamics. We are committed to meeting your business needs in China with speed, cost-effectiveness, and professionalism.

Our services are designed to minimize and eliminate the risks associated with importing defective merchandise. Through on-site inspections, we ensure purchase order requirements are met and that all evaluated merchandise complies with the buyer's specifications. V-inspected offers competitive pricing and employs highly qualified and experienced professionals to deliver exceptional service to our clients.

Inspection Scope

Soft lines

Fabric, Plush Toys, Textile & Garments, Wedding Dresses, Footwear & Shoes, Sportswear &Gym wear, Luggage, Bags & Cases, Caps & Headwear, Leather Product , Etc.

Hard lines

Gifts, Toys, Crafts, Furniture & Furnishings, Home ware & Kitchenware, Bathroom Hardware, Sports & Entertainment Products, Porcelain & Ceramics, Wood Boards & Blocks, Construction Materials, Etc.

Electronic & Mechanical Products

Consumer Electronics, Home Appliance, Computer Hardware& Parts, Electrical Equipment & Components, Electronic Accessories, Lights & Lighting, Telephone & Mobiles, Electrical Vehicles, Machinery & Parts, Metal Sheet & Coil, Industrial Parts Etc.

Product Inspections

V-inspection's quality control services verify product quality and quantity to predetermined specifications. The decrease in product life cycles and time-to-market increases the challenge to deliver quality products in a timely manner. When your product fails to meet your quality specifications for market acceptance, the result can be loss of good will, product and revenues, delayed shipments, wasted materials, and the potential risk of a product recall.

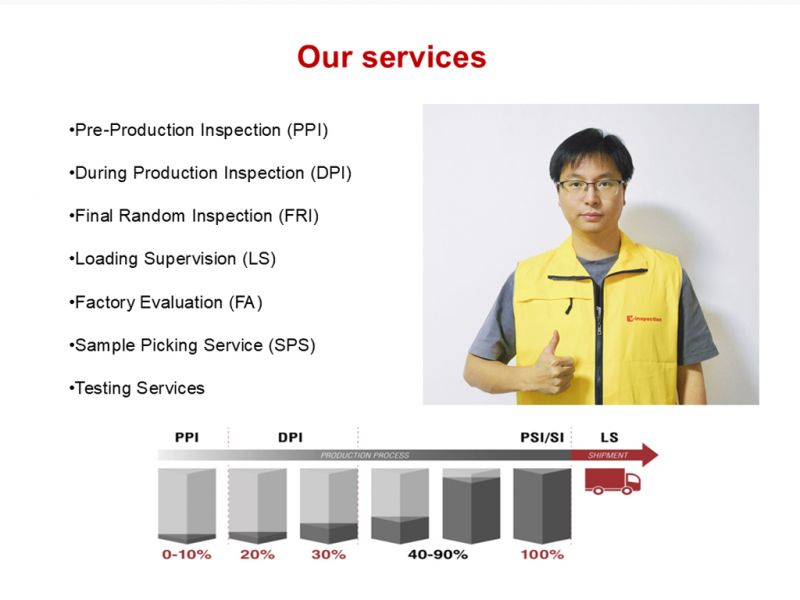

Pre-Production Inspection (PPI): Ensuring Quality from the Start

The PPI process involves a comprehensive evaluation of raw materials, accessories, components, and simi-finished and finished samples against client specifications and reference samples. This proactive approach aims to identify potential product issues and recommend solutions before production commences. The PPI provides assurance that your product specifications are clearly understood and adhered to from the outset.

PPI Scope:

■ Factory production Lines &Capabilities

■ Factory Facilities & Equipment

■ Raw Materials, Main Components & Accessories

■ Semi-finished Samples

■ Finished Samples (Partial)

During Production Inspection (DPI):Quality Assurance Throughout Manufacturing

When 20%-30% of your goods are completed, we conduct a DPI to evaluate the quality of semi-finished and finished items against your specifications. This inspection ensures that quality and compliance are maintained throughout production. The DPI also facilitates early detection and correction of any issues, minimizing potential delays.

During Production Inspection (DPI) Includes:

■ Monitoring of production status during manufacturing.

■ Evaluation of production line and timeline verification.

■ Random sampling of semi-finished and finished products

■ Verification of package and packaging material details.

■ Overall assessment and recommendations.

During Production Inspection (DPI) Includes:

■ Monitoring of production status during manufacturing.

■ Evaluation of production line and timeline verification.

■ Random sampling of semi-finished and finished products

■ Verification of package and packaging material details.

■ Overall assessment and recommendations.

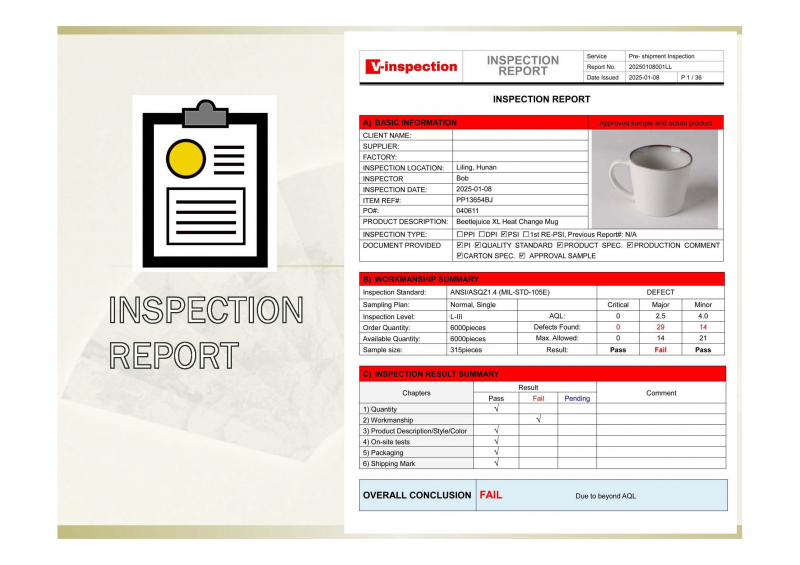

Pre-Shipment Inspection (PSI): Final Quality Verification

A Pre-Shipment Inspection (PSI) is conducted when goods are 100% completed, packed, and ready for shipment. Our inspectors perform random sampling of finished goods according to the international statistical standard MIL-STD-105E (ISO 2859-1). The PSI ensures that the finished products fully comply with your specifications.

Pre-shipment Inspection (PSI) Includes:

■ Quantity Verification

■ Style and Color Verification

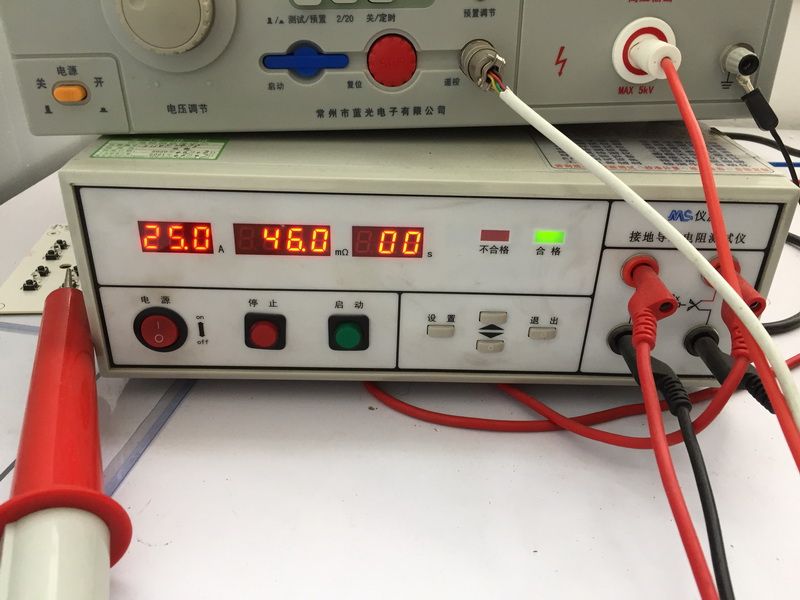

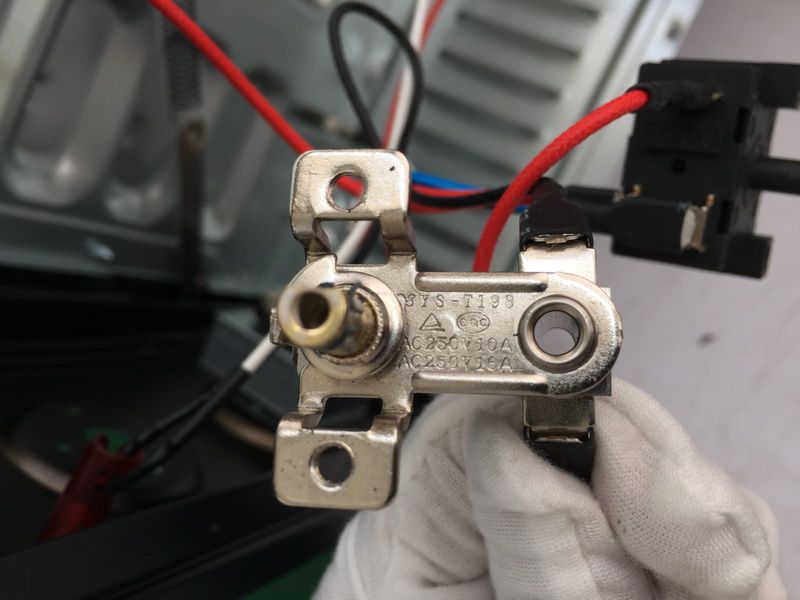

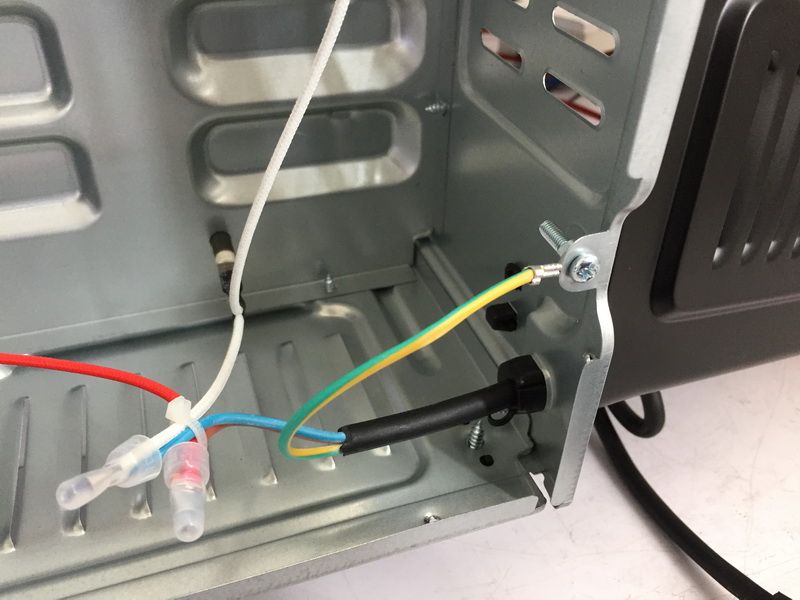

■ Function and Safety Testing

■ Workmanship Evaluation (General Appearance)

■ Size Specification Verification (if required)

■ Shipping Marks Verification

Pre-shipment Inspection (PSI) Process:

Prior to each PSI, an account manager will provide the client with a 'job file' for approval. This document outlines the complete inspection scope, allowing clients to customize the inspection by adding or removing specific points. Upon client approval, signature, and seal, the job file becomes the inspection agreement and serves as the inspector's checklist.

Prior to each PSI, an account manager will provide the client with a 'job file' for approval. This document outlines the complete inspection scope, allowing clients to customize the inspection by adding or removing specific points. Upon client approval, signature, and seal, the job file becomes the inspection agreement and serves as the inspector's checklist.

During the inspection, the account manager remains available to address any client questions or requirements. If significant defects or discrepancies are discovered, the account manager will promptly notify the client. A detailed inspection report will be delivered to the client within 24 hours of inspection completion.Following delivery, our after-sales service team will contact the client for feedback.

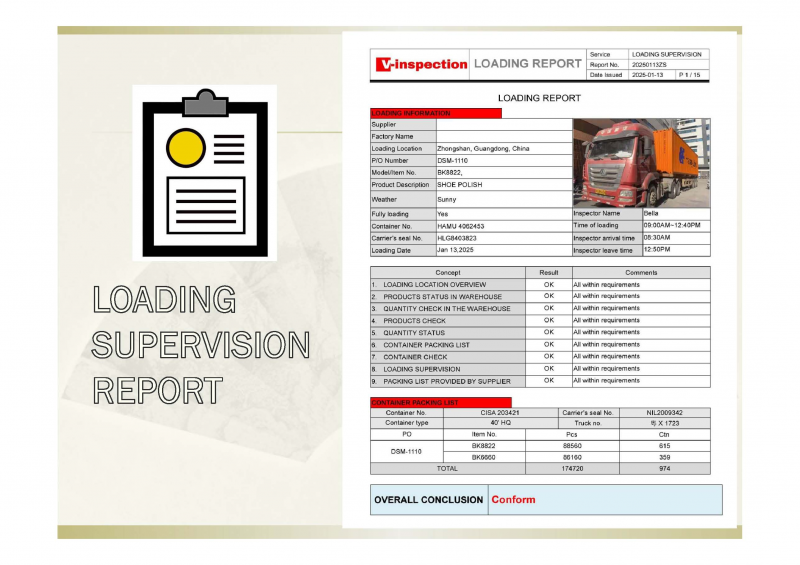

Loading Supervision (LS)

Our inspectors oversee the entire loading process at any location. This includes evaluating the shipping containers condition, verifying product information, quantities, and packaging, and supervising the loading itself. To mitigate the risk of post-loading product substitution, a V-inspection seal is applied.

Container Loading Supervision (LS) Procedure:

■ Document weather conditions, container arrival/truck details.

■ Inspect container interior and exterior for damage, moisture, perforations, and odors.

■ Verify loaded goods quantity and document outer packaging condition (master cartons/pallets)

■ Select and examine random sample cartons to confirm compliance with customer specifications.

■ Supervise loading to minimize damage and optimize space utilization.

■ Secure container with customer and V-inspection seals.

■ Record seal numbers and container departure time.

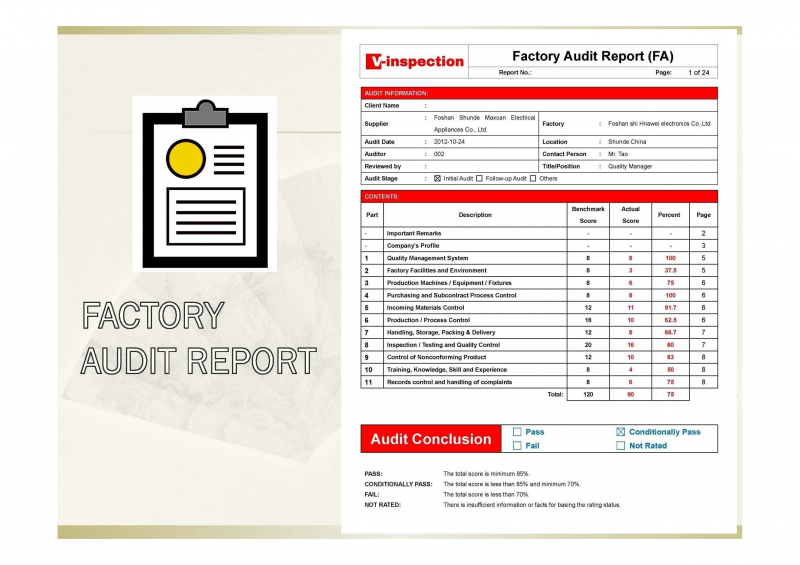

Factory Evaluation: Ensuring Supplier Suitability

Prior to order placement, we assess the suppliers production capabilities, machinery, management, quality procedures, operations, and processes. We also ensure the supplier understands your specific quality requirements. This evaluation guarantees the selection of appropriate suppliers and clear communication of your quality specifications. We tailor the evaluation program to your specific needs and focus.

Factory Evaluation Coverage:

■ Scale and Organization

■ Quality Control System

■ Manufacturing Process

■ Facilities

■ Equipment calibration

Sample Picking Service (SPS): Ensuring Representative Samples

Sample Picking Service (SPS) facilitates the selection of shipment or testing samples, enabling you to accurately assess production quality and compliance with market standards. V-inspection ensures random sample selection from the mass production lot, preventing factory-arranged samples that may not reflect actual production quality.

Purpose of Sample Picking Service (SPS):

Purpose of Sample Picking Service (SPS):

The SPS aims to select cartons randomly for accurate inspection results, reflecting the true quality of the mass production. Additionally, V-inspection employs specific carton sealing procedures to identify selected and sealed cartons, as well as those re-packed and sealed by us. This service aids clients in evaluating inspector performance, particularly when quality issues arise.

Sample Report Preview:

Contact Information

- Company: Voice Of Inspection And Trading Limited

- Address: Shennan road, Shenzhen, Fuzhou,, Wuhan, China

- Telephone: 86-19986935036

- Mobile: 86-19986935036

Company Profile

- Voice of inspection and trading limited

- [ China ]

-

-

Quality Inspection Service

V-inspection is an international inspection company, established in Hong Kong and mainland China in 2015. We offer comprehensive third-party quality control services, including inspections, factory audits (FA and SCA), and customized quality solutions for hard goods,electrical and electronic goods, and soft goods. Our services ensure global buyers a secure and reli...

Basic Information

- Business Type: Business Services

- Company Products / Services: third party inspection service

- Year Established: 2015

- Number of Employees: 26-50

- Website: https://www.v-inspection.com