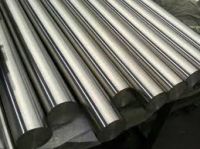

Stainless Steel Rebar

- Location: PHILIPPINES

- FOB Price: 380 ~ 400 ( Negotiable )

- Minimum Order Quantity: 50 Ton

- Packaging Detail: BUYER REQUEST

- Delivery Time: 7-21 DAYS Day

- Supplying Ability: 260000

- Payment Type: T/T, Western Union, Money Gram

Product Description click to expand contents

Stainless Steel Rebar

. Stainless Steel Rebar: This high-end type of rebar is made from stainless steel, offering superior corrosion resistance and strength. It is used in highly demanding environments, including underwater structures, industrial plants, and places with extreme exposure to corrosive substances.

6. Composite Rebar: Made from materials like fiberglass or carbon fiber, composite rebar is used in specific applications where traditional steel rebar may not be suitable. These are lighter and resistant to corrosion but are more expensive.

Benefits of Concrete Steel:

Enhanced Strength: The addition of concrete steel to a concrete structure provides significant improvement in its strength, especially in tension. Concrete can handle compressive forces, but it is the reinforcing steel that allows the concrete to handle tensile and shear stresses.

Durability: Reinforced concrete structures with concrete steel are highly durable and can withstand heavy loads, vibrations, and natural forces, making them long-lasting and safe.

Corrosion Resistance: Depending on the coating (e.g., galvanized or epoxy-coated), concrete steel can be resistant to corrosion, extending the lifespan of the structure.

Versatility: Concrete steel can be formed into various shapes and sizes to suit different types of construction projects, offering flexibility in design and application.

Cost-Effective: Reinforced concrete is often more cost-effective than using other materials like steel beams, as concrete is cheaper, and steel reinforcement significantly increases its strength.

Drawbacks:

Corrosion: Unprotected concrete steel (e.g., uncoated rebar) is vulnerable to corrosion when exposed to moisture, salt, or chemicals, which can weaken the structure over time.

Brittleness: Concrete, by nature, can be brittle under certain circumstances, and if there is any failure or cracking in the concrete, it could lead to issues with the steel reinforcement as well.

Labor-Intensive Installation: The placement and tying of rebar in concrete construction require skilled labor, which can add to the overall time and cost of the project.

Weight: Concrete steel adds significant weight to structures, which may require additional consideration in the design phase, especially for high-rise buildings or structures with specific weight limits.

Summary:

Concrete steel (reinforcing steel or rebar) is essential for reinforcing concrete structures, providing strength to handle tension, shear, and other forces that concrete alone cannot manage. Available in different forms such as hot-rolled, galvanized, or stainless steel, it is used across various industries, including construction, transportation, marine, and infrastructure. The use of concrete steel enhances the durability, stability, and longevity of concrete structures, making them capable of withstanding extreme conditions while maintaining their integrity over time.

. Stainless Steel Rebar: This high-end type of rebar is made from stainless steel, offering superior corrosion resistance and strength. It is used in highly demanding environments, including underwater structures, industrial plants, and places with extreme exposure to corrosive substances.

6. Composite Rebar: Made from materials like fiberglass or carbon fiber, composite rebar is used in specific applications where traditional steel rebar may not be suitable. These are lighter and resistant to corrosion but are more expensive.

Benefits of Concrete Steel:

Enhanced Strength: The addition of concrete steel to a concrete structure provides significant improvement in its strength, especially in tension. Concrete can handle compressive forces, but it is the reinforcing steel that allows the concrete to handle tensile and shear stresses.

Durability: Reinforced concrete structures with concrete steel are highly durable and can withstand heavy loads, vibrations, and natural forces, making them long-lasting and safe.

Corrosion Resistance: Depending on the coating (e.g., galvanized or epoxy-coated), concrete steel can be resistant to corrosion, extending the lifespan of the structure.

Versatility: Concrete steel can be formed into various shapes and sizes to suit different types of construction projects, offering flexibility in design and application.

Cost-Effective: Reinforced concrete is often more cost-effective than using other materials like steel beams, as concrete is cheaper, and steel reinforcement significantly increases its strength.

Drawbacks:

Corrosion: Unprotected concrete steel (e.g., uncoated rebar) is vulnerable to corrosion when exposed to moisture, salt, or chemicals, which can weaken the structure over time.

Brittleness: Concrete, by nature, can be brittle under certain circumstances, and if there is any failure or cracking in the concrete, it could lead to issues with the steel reinforcement as well.

Labor-Intensive Installation: The placement and tying of rebar in concrete construction require skilled labor, which can add to the overall time and cost of the project.

Weight: Concrete steel adds significant weight to structures, which may require additional consideration in the design phase, especially for high-rise buildings or structures with specific weight limits.

Summary:

Concrete steel (reinforcing steel or rebar) is essential for reinforcing concrete structures, providing strength to handle tension, shear, and other forces that concrete alone cannot manage. Available in different forms such as hot-rolled, galvanized, or stainless steel, it is used across various industries, including construction, transportation, marine, and infrastructure. The use of concrete steel enhances the durability, stability, and longevity of concrete structures, making them capable of withstanding extreme conditions while maintaining their integrity over time.

Contact Information click to expand contents

- Contact Person: Ms. GARCES JAMILLE BALLESTEROS (Director)

- Company: Elite Goods Trading

- Address: Philippines

- Telephone: 63-9451574014

- Mobile: 639451574014

Company Profile click to expand contents

- Elite Goods Trading

- [ Philippines ]

-

-

Overview: Elite Goods Trading Company is a dynamic and innovative trading company based in Manila, Philippines. Specializing in the import and export of high-quality goods, we cater to a wide range of industries, ensuring the delivery of superior products that meet the diverse needs of our clients. Our focus is to foster long-term relationships with both suppliers and customers through professi...

Basic Information

- Business Type: Others

- Company Products / Services: bpa paper,label paper,jumbo thermal paper,tissue paper,jumbo tissue paper,napkin roll,tissue paper roll,jumbo napkin roll,wax paper,bond paper,absorbent paper,copper tube,copper sheet,copper wire coil,coated steel,coated aluminum

- Year Established: 2023

- Number of Employees: 51-100