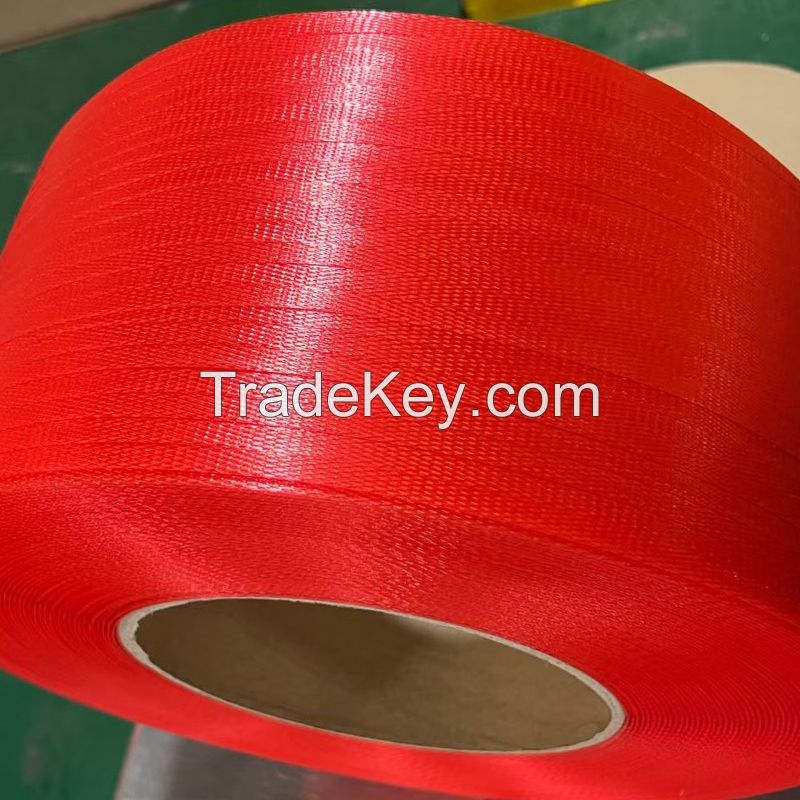

PP packing belt, known as polypropylene, is a lighter type of common plastics. The main material of PP packing belt is polypropylene wire drawing resin. Because of its good plasticity, strong breaking tension, bending resistance, light specific gravity, convenient use and other advantages, the processed binding belt has been widely used in various fields. PP stands for polypropylene. There are many brands of polypropylene. T30S polypropylene raw material is used for the production of packing belt (the best effect). Appearance of PP packing belt: translucent to opaque, transparent film. Combustibility: Combustible in flame. After leaving the flame, extinguish it slowly or continue to burn. When burning, the upper end of the flame is yellow and the lower end is blue; There are melting and dripping phenomena. The smell of paraffin can be heard.

1. Polypropylene (PP) is the main raw material, which is made of polypropylene wire drawing grade resin. Due to its good plasticity, it breaks

It has the advantages of strong force, bending fatigue resistance, small density, good tensile impact performance, convenient use, etc., and is now used in various fields

It plays an extensive role in.

2. Applicable to all kinds of packing belt machines in all walks of life (semi-automatic, full-automatic, manual packing machines)

3. Strong viscosity, large tension, light weight, corrosion resistance, beautiful appearance, high-grade

4. Bright color, yellow, white, black and other colors, you can choose

5. According to customer requirements and samples, we can produce special packing belts such as printing words and icons.