Molybdenum Disulfide MOS2 Powder For Lubrication

- Location: China

- FOB Price: 16.5 ~ 17.5 / Kilogram ( Negotiable )

- Minimum Order Quantity: 1 Kilogram

- Packaging Detail: 25kg/bag, plastic bag

- Delivery Time: within 10 days Day

- Supplying Ability: 300 Ton / Year

- Payment Type: Western Union, D/P, L/C, T/T

Product Description

Molybdenum Disulfide Introduction:

Molybdenum disulfide (MoS2 powder) is an inorganic compound composed of molybdenum and sulfur. Its chemical formula is MoS2. Like most mineral salts, MoS2 has a high melting point but begins to sublime at a relatively low 450ºC. This property is useful for purifying compounds.

In addition to its lubricity, MoS2 powder is also a semiconductor. It is also known that when doped with an electrostatic field, it and other semiconductor transition metal chalcogenides become superconductors on its surface.

Molybdenum disulfide and related molybdenum sulfides are efficient catalysts for hydrogen evolution, including the electrolysis of water; thus, are possibly useful to produce hydrogen for use in fuel cells.

MoS2 powder also possesses mechanical strength, electrical conductivity, and can emit light, opening possible applications such as photodetectors. MoS2 has been investigated as a component of photoelectrochemical (e.g. for photocatalytic hydrogen production) applications and for microelectronics applications. Feel free to send an inquiry to get the latest price if you would like to buy Molybdenum Disulfide MoS2 Powder in bulk.

MolybdenumDisulfideCharacteristics:

Molybdenum disulfide (MoS2) is a good solid lubricant in the following conditions:

1. Lubrication under wide temperature conditions: the application range of lubricating oil and grease is about 60°C to 350°C. Molybdenum disulfide solid lubricant can be applied to the operating temperature range of 270°C to 1000°C.

2, lubrication under heavy load conditions: general lubricating oil, fat oil film, can only bear a relatively small load. Once the load exceeds the limit value it can bear, the oil film breaks and the friction surface will bite. The solid lubricating film can bear an average load of 108Pa.

3, lubrication under vacuum conditions: under high vacuum conditions, the general evaporation of lubricating oil and fat is large, easy to destroy the vacuum environment, and affect the working performance of other components, so molybdenum disulfide solid lubricating material is generally used for lubrication.

4, lubrication under radiation conditions: under radiation conditions, the general liquid lubricant will polymerize or decompose, and lose the lubrication performance. Solid lubricants have good irradiation resistance.

5, the lubrication of conductive sliding surface: such as motor brush, conductive slider, solar satellite working in the vacuum and sliding electric contact friction, can be used carbon graphite or metal composite material for lubrication.

6, the environmental conditions are very bad occasions: bad environment occasions, such as transportation machinery, construction machinery, metallurgy and steel industry institutions, mining machinery and other transmission parts in the dust, sediment, high temperature and humidity and other harsh environment occasions to work, can use molybdenum disulfide solid lubricant for lubrication.

6, the occasion of corrosion environment: such as ship machinery, chemical machinery and other transmission parts in the water (steam), sea water and acid, alkali, salt and other corrosive media work, to withstand different degrees of chemical corrosion.The transmission parts working in this situation can be solid lubricated by molybdenum disulfide.

7, the environmental conditions are very clean occasions: electronics, textile, food, medicine, paper making, printing and other machinery in the transmission parts to avoid pollution, can be used MoS2 solid lubricant for lubrication.

8, no maintenance occasions: some transmission parts need no maintenance, some transmission parts in order to save costs, need to reduce the number of maintenance. In these occasions, the use of MoS2 solid lubricant is reasonable and convenient and can save money.

Molybdenum disulfide (MoS2) applications:

1.< 1.5um: Lubricating grease, Carbon brush, Coating, Release agent, Engineering plastic;

2. 3-6um: Lubricating grease, Carbon brush, Brake pad, Coating, Release agent, Engineering plastic;

3. 12-16um: Carbon brush, Brake pad, Powder metallurgy;

4. 16-30um: Carbon brush, Brake pad, Powder metallurgy.

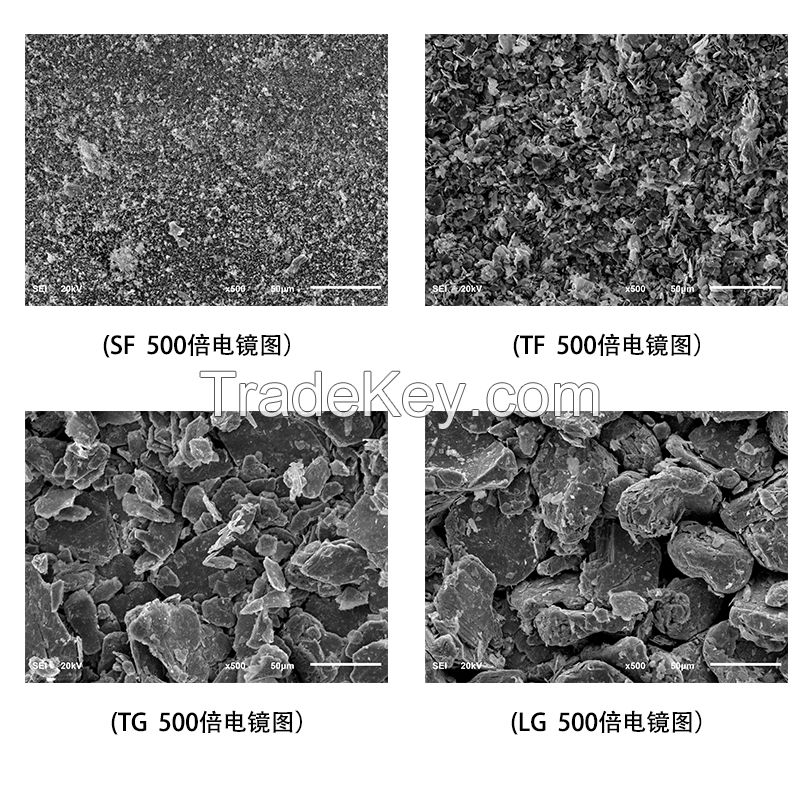

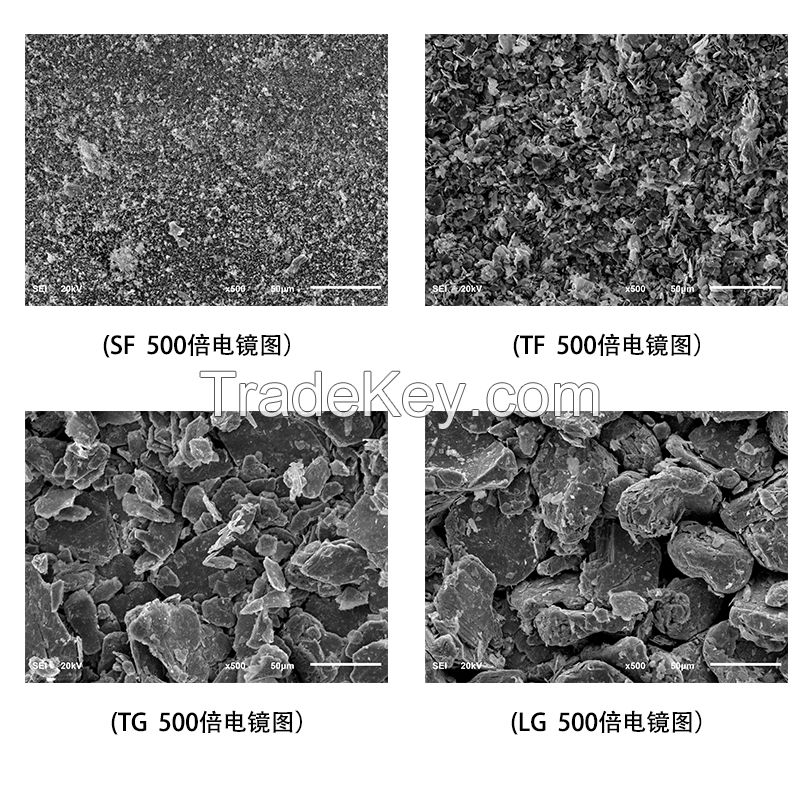

Electron microscopic photographs of molybdenum disulfide:

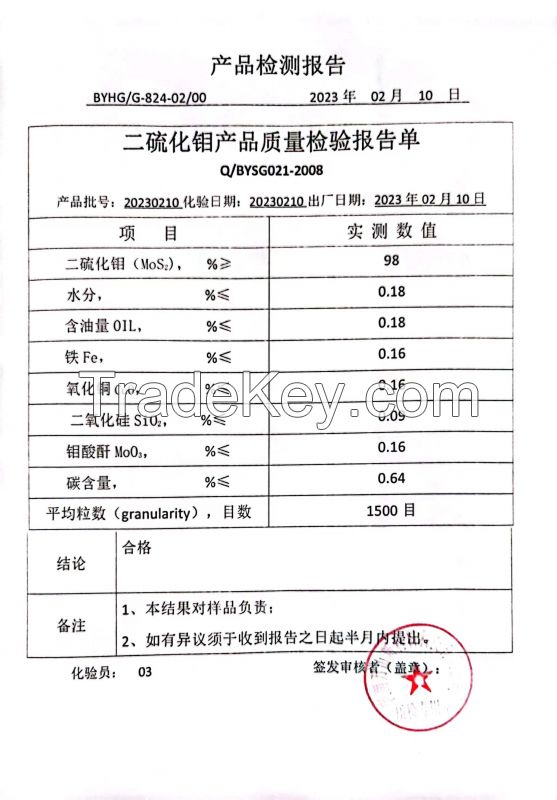

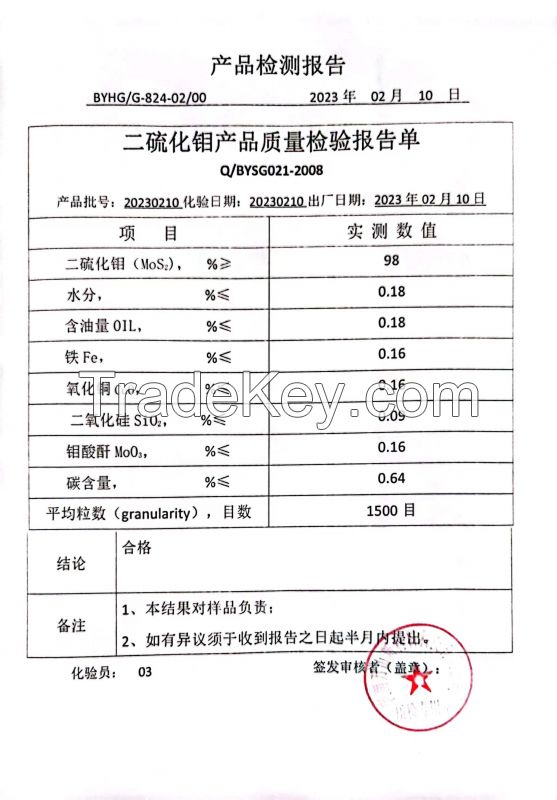

Testing report:

Molybdenum disulfide (MoS2 powder) is an inorganic compound composed of molybdenum and sulfur. Its chemical formula is MoS2. Like most mineral salts, MoS2 has a high melting point but begins to sublime at a relatively low 450ºC. This property is useful for purifying compounds.

In addition to its lubricity, MoS2 powder is also a semiconductor. It is also known that when doped with an electrostatic field, it and other semiconductor transition metal chalcogenides become superconductors on its surface.

Molybdenum disulfide and related molybdenum sulfides are efficient catalysts for hydrogen evolution, including the electrolysis of water; thus, are possibly useful to produce hydrogen for use in fuel cells.

MoS2 powder also possesses mechanical strength, electrical conductivity, and can emit light, opening possible applications such as photodetectors. MoS2 has been investigated as a component of photoelectrochemical (e.g. for photocatalytic hydrogen production) applications and for microelectronics applications. Feel free to send an inquiry to get the latest price if you would like to buy Molybdenum Disulfide MoS2 Powder in bulk.

MolybdenumDisulfideCharacteristics:

| Alias | Molybdenum sulfide | Chemical formula | MoS2 |

| Melting point ℃ | 2375.0 | Density g/ cm³ 14℃ | 4.5--4.80g |

| Molecular weight | 160.07 | CASNo. | 1317-33-5 |

| Hardness | 1.0--1.5 | Temperature resistance range (atmospheric environment) | -180℃--400℃ |

| Friction of friction | 0.03-0.05 | Compressive resistance | 30, 000 kg / cm² |

| Appearance | BlackSolidPowder | Chemical stability | strong corrosion resistance, in addition to nitric acid, king water, boiling hydrochloric acid does not work |

Molybdenum disulfide (MoS2) is a good solid lubricant in the following conditions:

1. Lubrication under wide temperature conditions: the application range of lubricating oil and grease is about 60°C to 350°C. Molybdenum disulfide solid lubricant can be applied to the operating temperature range of 270°C to 1000°C.

2, lubrication under heavy load conditions: general lubricating oil, fat oil film, can only bear a relatively small load. Once the load exceeds the limit value it can bear, the oil film breaks and the friction surface will bite. The solid lubricating film can bear an average load of 108Pa.

3, lubrication under vacuum conditions: under high vacuum conditions, the general evaporation of lubricating oil and fat is large, easy to destroy the vacuum environment, and affect the working performance of other components, so molybdenum disulfide solid lubricating material is generally used for lubrication.

4, lubrication under radiation conditions: under radiation conditions, the general liquid lubricant will polymerize or decompose, and lose the lubrication performance. Solid lubricants have good irradiation resistance.

5, the lubrication of conductive sliding surface: such as motor brush, conductive slider, solar satellite working in the vacuum and sliding electric contact friction, can be used carbon graphite or metal composite material for lubrication.

6, the environmental conditions are very bad occasions: bad environment occasions, such as transportation machinery, construction machinery, metallurgy and steel industry institutions, mining machinery and other transmission parts in the dust, sediment, high temperature and humidity and other harsh environment occasions to work, can use molybdenum disulfide solid lubricant for lubrication.

6, the occasion of corrosion environment: such as ship machinery, chemical machinery and other transmission parts in the water (steam), sea water and acid, alkali, salt and other corrosive media work, to withstand different degrees of chemical corrosion.The transmission parts working in this situation can be solid lubricated by molybdenum disulfide.

7, the environmental conditions are very clean occasions: electronics, textile, food, medicine, paper making, printing and other machinery in the transmission parts to avoid pollution, can be used MoS2 solid lubricant for lubrication.

8, no maintenance occasions: some transmission parts need no maintenance, some transmission parts in order to save costs, need to reduce the number of maintenance. In these occasions, the use of MoS2 solid lubricant is reasonable and convenient and can save money.

Molybdenum disulfide (MoS2) applications:

1.< 1.5um: Lubricating grease, Carbon brush, Coating, Release agent, Engineering plastic;

2. 3-6um: Lubricating grease, Carbon brush, Brake pad, Coating, Release agent, Engineering plastic;

3. 12-16um: Carbon brush, Brake pad, Powder metallurgy;

4. 16-30um: Carbon brush, Brake pad, Powder metallurgy.

Electron microscopic photographs of molybdenum disulfide:

Testing report:

Contact Information

- Contact Person: Ms. Anny Duan (Business Services Specialist)

- Company: SHENZHEN FEIGE COMPOSITE FIBER CO., LTD

- Address: No.4006,Dongfang Commercial Building, Baomin 2nd Road,Xixiang Street,Bao'an,Shenzhen,China, Shenzhen, Guangdong, China

- Zip/Postal: 518101

- Telephone: 86-13501570589

- Mobile: 86-13501570589

Company Profile

- SHENZHEN FEIGE COMPOSITE FIBER CO., LTD

- [ China ]

-

-

Fiber Co., Ltd. is a wholly-owned subsidiary of was in 2017Shenzhen Yataida High-Tech. Co.Ltd.established; we are specialist inngingcomposite fibersseverals3Olaboratory is equipped with a full set of advanced instrumentW exportedto Germany, Turkey,,America,countriesThe key of our surviving in the market during the years is good quality, reasonable price, proper technical & commercial support an...

Basic Information

- Business Type: Manufacturing

- Company Products / Services: fiberglass roving,chopped fiberglass,chopped carbon fiber,milled fiberglass,milled carbon fiber

- Year Established: 2017

- Number of Employees: 11-15

- Website: www.yataida.net