DN15~DN600

Brief introduction of large diameter sonic nozzle method gas flow device

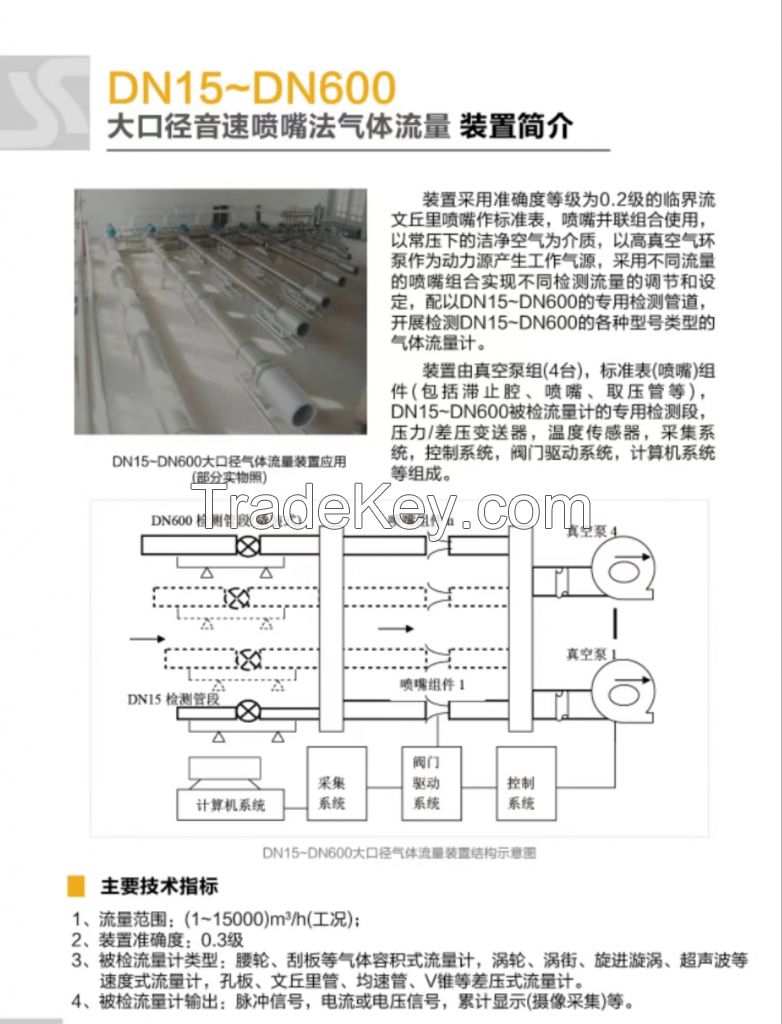

A critical flow Venturi nozzle with an accuracy of 0.2 is used as the standard table. The nozzle is combined in parallel. With clean air under normal pressure as the medium, high truth air ring pump as the power source to produce working air source, using different flow nozzle combination to achieve different detection flow adjustment and setting, with DN15~DN600 special detection pipeline, to carry out the detection of DN15~DN600 of various types of gas flowmeters.

The device consists of a vacuum pump group (4 sets), standard table (nozzle) assembly (including stagnation chamber, nozzle, pressure tube, etc.). DN15~DN600 special test section of the flowmeter to be inspected. Pressure/differential pressure transmitter, temperature sensor, acquisition system, control system, valve drive system, computer system, etc.

Main technical index

1, flow range :(1~15000)m3/h(working condition);

2, device accuracy :0.3 level

3, the type of the inspected flowmeter, waist wheel, scraper and other gas positive displacement flowmeter, turbine, vortex street, precession vortex, ultrasonic, etc

Velocity flowmeter, orifice plate, Venturi tube, uniform pitot tube, V cone isometric pressure flowmeter.

4, the output of the inspected flowmeter, pulse signal, current or voltage signal, cumulative display (camera collection ).